Accreditations/Affiliations

I.A.S., ISO 17025

AASHTO AAP

AWS

I.C.C.

DSA

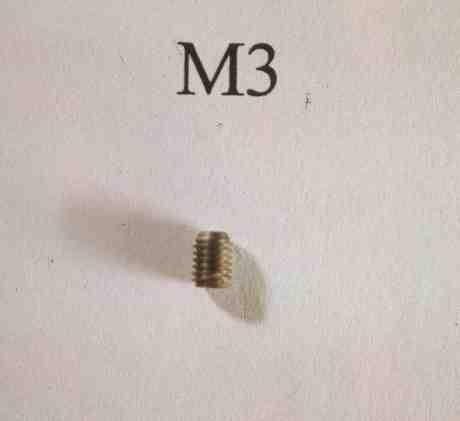

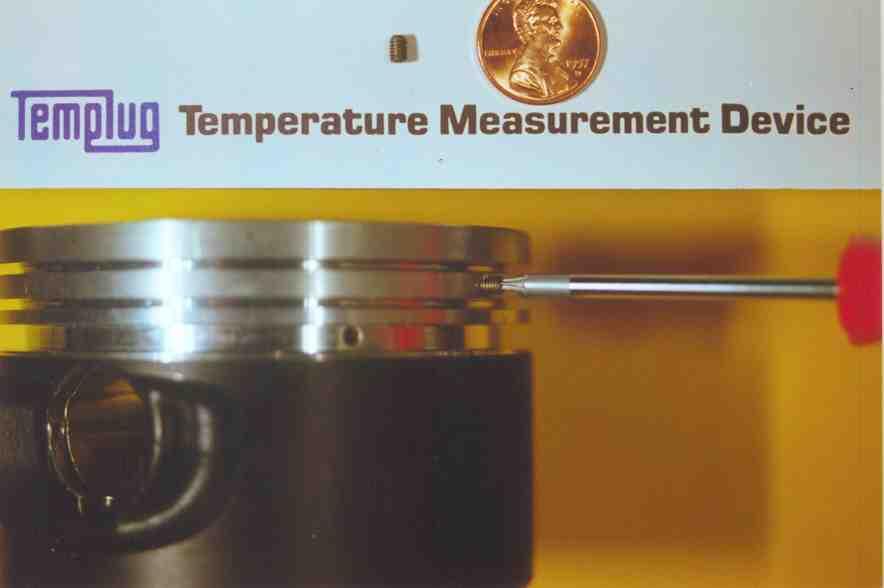

TEMPLUG TEMPLUG is a temperature sensitive steel set-screw and is used for determining the maximum temperature in locations that are difficult to instrument using conventional "thermocouple type" techniques (moving engine parts, turbine blades, and bearings are good examples of typical applications). The part being tested does not need to be made of steel; nickel alloys, aluminum, composites, ceramics can be tested with this technique. By drilling and tapping, a TEMPLUG can be installed directly into the location at which temperature needs to be measured. Under suitable conditions, TEMPLUG can measure maximum temperatures accurate to within ± 3%.

View or Download TEMPLUG User Manual (PDF Format)

M3 TEMPLUG

M1.6 TEMPLUG with installation handle

Drilled and tapped holes, ready for TEMPLUG installation

M3#2 TEMPLUG being installed

M1.6 TEMPLUG and two turbine blades contact Maria at 510-835-3142 ext. 177 email: aiden AT testing DASH engineers.com |

||||||||||||||||||||||||||||||||||||

Testing Engineers | 2811 Teagarden St., San Leandro, CA 94577 | P: (510) 835-3142 | F: (510) 834-3777 | E-mail Us At: info AT testing DASH engineers.com