Accreditations/Affiliations

I.A.S., ISO 17025

AASHTO AAP

AWS

I.C.C.

DSA

Failure Analysis & Materials ConsultingWhy do failure analysis ? a) Diagnosis of failure for corrective action to prevent re-occurrence and improve quality b) Product liability litigation c) Insurance claims d) Accident reconstruction

Typical causes of equipment / component failure: a) Improper Use b) Mis-assembly c) Inadequate Maintenance d) Improper mechanical design e) Incorrect material selection

Who would benefit from failure analysis? a) Industry, including construction, manufacturing, chemical, pharmaceutical, and food processing. b) Legal professionals c) Insurance industry

How can TEI help? TEI has been providing forensic expertise in material failures and consulting services since its inception. This service has catered to construction and manufacturing industries as well as legal and insurance businesses. Our licensed engineers have provided independent expertise and have been retained as expert witnesses in a number of legal cases. Our state of the art laboratory resources are extensively utilized to help our experts in root cause analysis. We also provide consulting in materials related projects including preparing project specifications.

Typical Projects a) Corrosion of Heat Exchanger Piping b) Ship Propeller Shaft Failure Analysis c) Corrosion Evaluation of Wet Exhaust System of a Power Generator d) Fire damage investigation of structural steel e) Corrosion of fire protection sprinkler system piping f) Failure analysis of orthopedic implants

g) Corrosion damage investigation evaluation of welds in stainless steel tanks in a fertilizer plant h) Failure analysis of coatings on electronic components i) Root cause analysis of dental needle failure

Testing capabilities of TEI essential to failure investigation

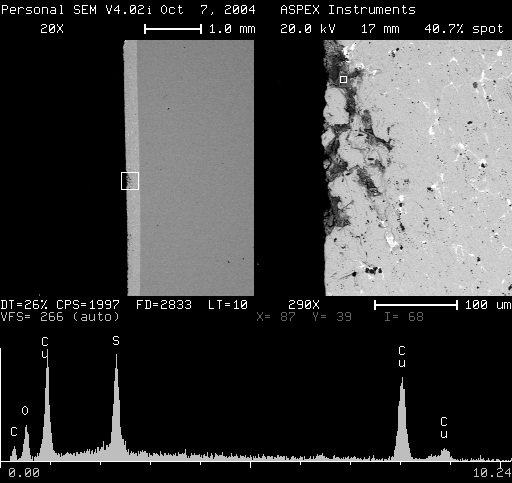

a) Metallography and Digital Micrography b) Technical Photography c) Scanning Electron Microscopy (SEM) & Energy Dispersive X-ray (EDX) d) Microhardness Testing/Depth of Case & Coatings e) Mechanical Testing f) Corrosion Evaluation g) Non-destructive testing (NDT) h) Pressure Testing

For more information contact Hossein (Hoss) Arbabi, Ph.D., P.E. at 510.835.3142 X199 |

Testing Engineers | 2811 Teagarden St., San Leandro, CA 94577 | P: (510) 835-3142 | F: (510) 834-3777 | E-mail Us At: info AT testing DASH engineers.com