Accreditations/Affiliations

I.A.S., ISO 17025

AASHTO AAP

AWS

I.C.C.

DSA

NewsletterThe TEI Newsletter

The term shotcrete has come to mean concrete sprayed from a nozzle, with the material delivered by a truck, or mixed on site. This latter technology is generally referred to as gunite, which is often used for swimming pools, and has virtually no coarse aggregate. In addition, the gunite system mixes the water with the sand and cement at the nozzle, which virtually eliminates waste in terms of unused material.

The significance of shotcrete is its ease of application, and the freedom from complex formwork. Designers and builders, both of whom are constantly looking for methods of reducing construction time, immediately recognized these benefits, and the use of shotcrete has steadily grown since the early days. Current fast-track construction schedules have motivated builders to push the envelope of shotcrete applications, increasing the complexity of the structures being built with this material. What is Testing Engineers part in all of this? We aren’t designers or builders, but we do provide special inspection, and for shotcrete, that often involves a mock-up or pre-qualification panel. This panel mimics the most congested area of concrete placement, and allows the engineers and building officials the luxury of ensuring their design is possible by way of the shotcrete application. Unlike conventionally placed concrete, there is no way to consolidate (vibrate) the material after placement. Heavily

Though no newcomer to the construction industry, shotcrete is gaining in popularity, due in part to the efficiency of placement. As this trend continues, Testing Engineers will be called to inspect increasingly challenging shotcrete applications.

|

Testing Engineers | 2811 Teagarden St., San Leandro, CA 94577 | P: (510) 835-3142 | F: (510) 834-3777 | E-mail Us At: info AT testing DASH engineers.com

Shotcrete has been around since the early part of the 20th century, and though many people think of it as new technology, the first commercial machines were available by 1915. In fact, when shotcrete, or “pneumatically applied concrete” was new, there were many different names for it – Blastcrete, Nucrete, Spraycrete…even Shotcrete was a trade name, but it is the one that stuck.

Shotcrete has been around since the early part of the 20th century, and though many people think of it as new technology, the first commercial machines were available by 1915. In fact, when shotcrete, or “pneumatically applied concrete” was new, there were many different names for it – Blastcrete, Nucrete, Spraycrete…even Shotcrete was a trade name, but it is the one that stuck.

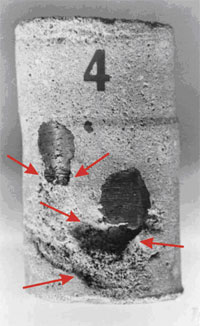

reinforced sections such as beam-column connections and shear walls can be difficult to shoot, with poorly consolidated concrete and voids or “shadows” behind rebar. The problems can be due to inexperience on the part of the nozzleman, the crowded configuration of the steel, or a combination of both. Regardless of the cause, the result is a deficient building component that could compromise the structural integrity of the project.

reinforced sections such as beam-column connections and shear walls can be difficult to shoot, with poorly consolidated concrete and voids or “shadows” behind rebar. The problems can be due to inexperience on the part of the nozzleman, the crowded configuration of the steel, or a combination of both. Regardless of the cause, the result is a deficient building component that could compromise the structural integrity of the project. Testing Engineers has an inspector observe the shooting of the pre-construction panel, where the mix design and nozzleman qualifications are checked. The real test comes several days later, however, when the panel is cored. While most of the time we try to avoid rebar when coring, in this instance a core is removed at a bar crossing, to observe the consolidation of the shotcrete in a congested area. ACI chapter 506.2, section 1.7 states that cores shall be graded from 1 (best) to 5 (worst). The scores reflect the amount of shadowing found adjacent to reinforcing steel, the incidence of rock pockets and sandy layers, and the general consolidation of the material. An acceptable average score for three cores shall be at least 2.5, and individual cores with a score greater than 3 are unacceptable. In addition to the cores removed for observation, cores are also removed for compressive strength testing.

Testing Engineers has an inspector observe the shooting of the pre-construction panel, where the mix design and nozzleman qualifications are checked. The real test comes several days later, however, when the panel is cored. While most of the time we try to avoid rebar when coring, in this instance a core is removed at a bar crossing, to observe the consolidation of the shotcrete in a congested area. ACI chapter 506.2, section 1.7 states that cores shall be graded from 1 (best) to 5 (worst). The scores reflect the amount of shadowing found adjacent to reinforcing steel, the incidence of rock pockets and sandy layers, and the general consolidation of the material. An acceptable average score for three cores shall be at least 2.5, and individual cores with a score greater than 3 are unacceptable. In addition to the cores removed for observation, cores are also removed for compressive strength testing.